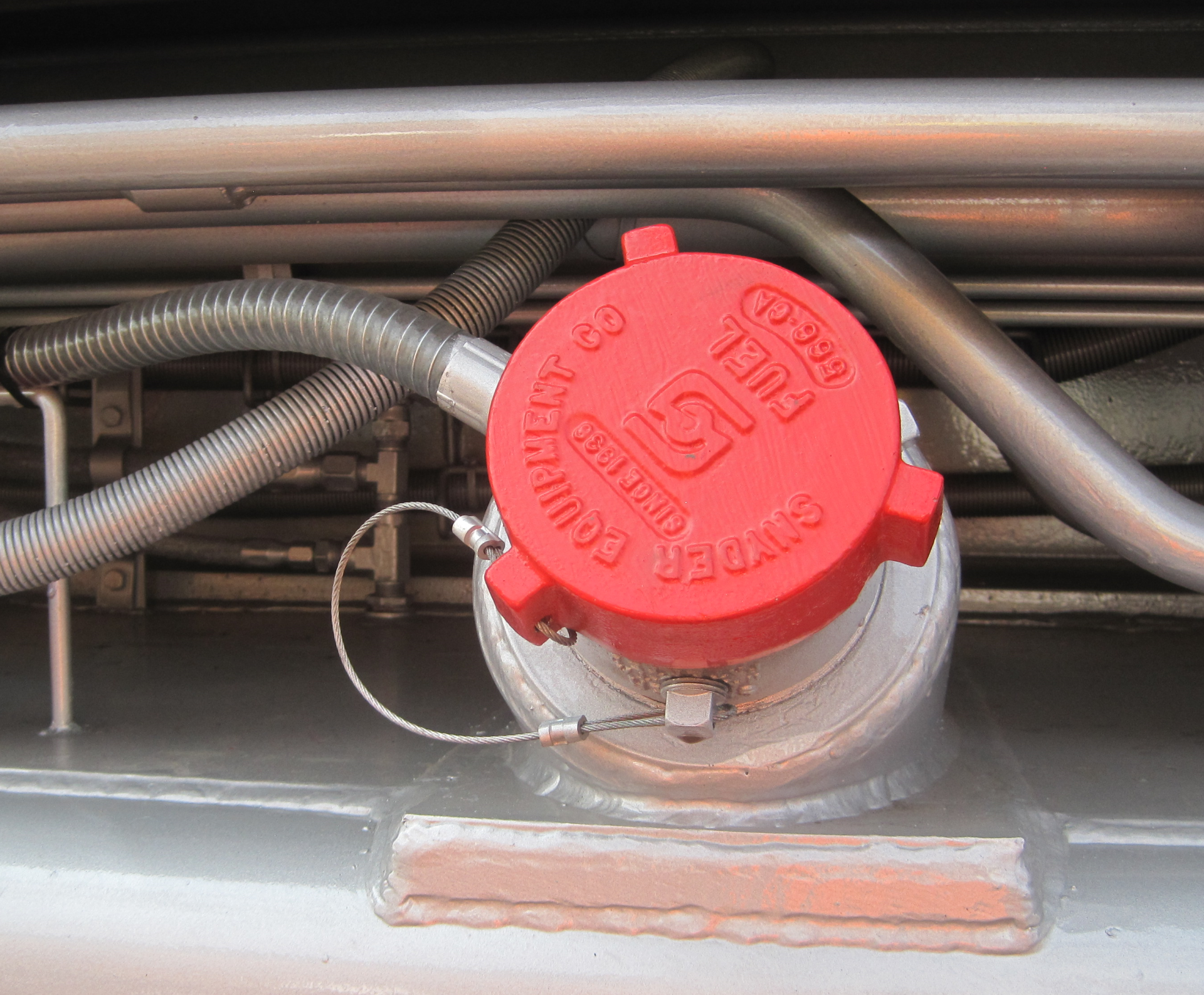

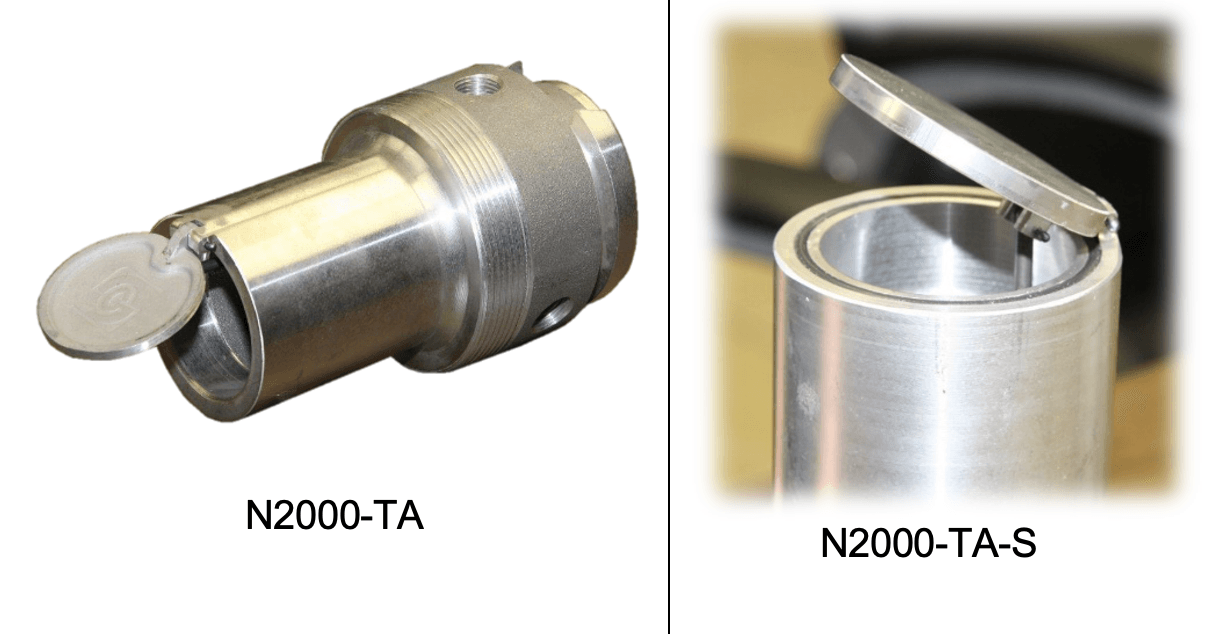

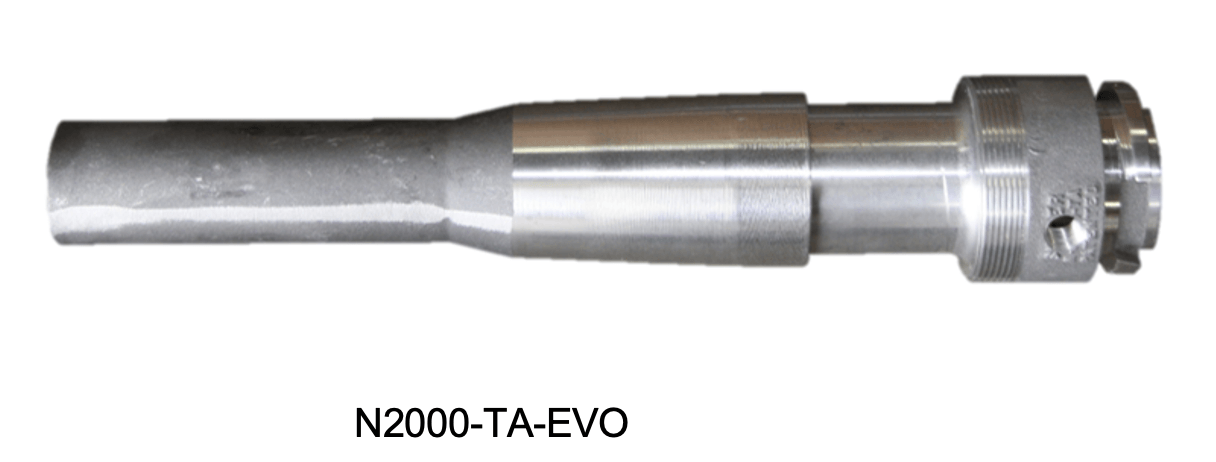

Tank Adaptor and Vent Hose

NOTE: Some GE locomotives require a special mounting assembly for proper tank adaptor installation. Contact Snyder Equipment if you are unsure about the proper kit for your application.

766-AR Tool

766-AR tools are used to remove and install Snyder tank adaptors. The red and black pins allow you to properly orient the tank adapter to keep the flapper hinge between the 11 o’clock and 1 o’clock position.

AR tools are available for ¾” and 1” drive sockets.

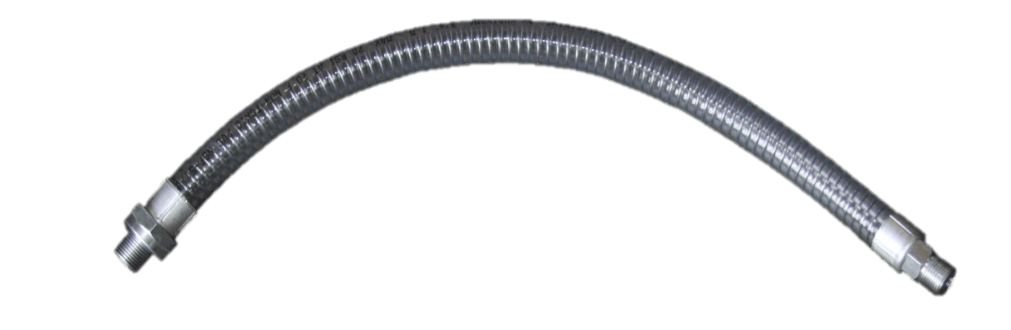

Vent Hoses

Snyder vent hoses are designed to provide the proper amount of air to operate 1720-DS nozzles. They feature special fittings to maintain a 5/8” ID throughout the hose and fittings.

Vent hoses come in a variety of standard lengths to fit specific locomotives.

Why are Snyder vent hoses critical to proper nozzle operation?

HOW TO ORDER VENT HOSES

How to Order Snyder Vent Hoses

Lay the hose out straight and measure the distance between the ends of the fitting threads. Choose the proper length of hose from the table below. Common locomotive configurations are included.

Contact Snyder if you need a custom length for your application.

| Snyder Part Number | Hose Length | Typical Locomotive Models |

|---|---|---|

| 713-SW-18 | 18” | SW1500, MP15DC |

| 713-SW-22 | 22” | Most SD70, SD70M |

| 713-SW-24 | 24” | Some SD70 |

| 713-SW-26 | 26” | GP15, GP38/38AC, GP38-2, GP50, GP59, GP60, SD60, SD60I, SD60M, SD80MAC |

| 713-SW-30 | 30” | Most GE locomotives |

| 713-SW-34 | 34” | SW1001 |

| 713-SW-38 | 38” | GP40, GP40-2, SD40, SD40-2 |

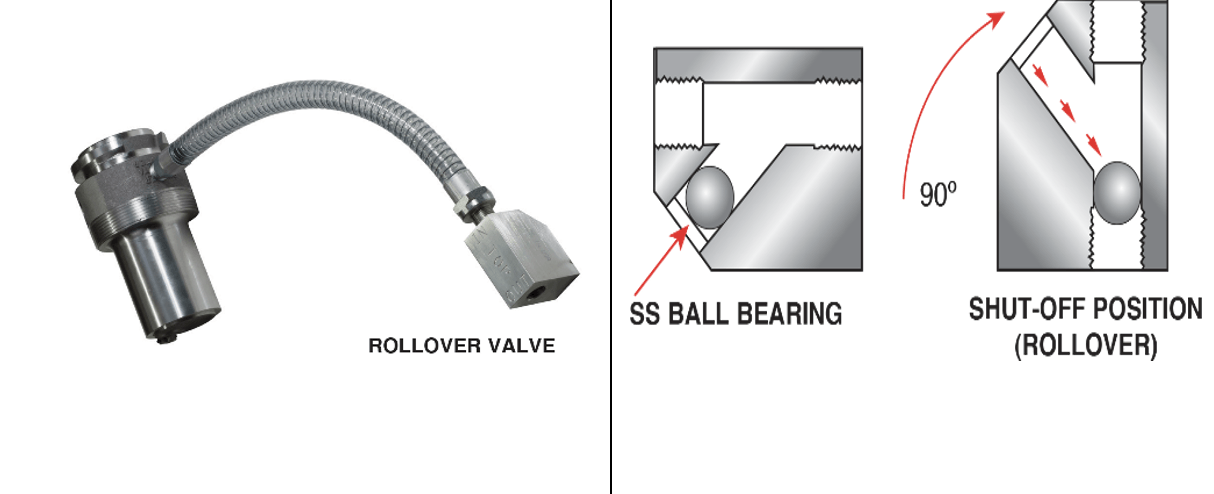

Rollover Kits

Rollover kits prevent fuel spills from the vent hose in case of locomotive derailment that cause a rollover. They contain a stainless ball bearing that plugs the vent hose opening. See brochure below: