Fuel Nozzles

Snyder 1720-DS fuel nozzles – Setting the fueling standard in the rail industry for over 40 years.

The Snyder 1720-DS nozzle combines high flow rates with an automatic shutoff feature, allowing efficient fueling with minimum need for operator control.

The 1720-DS nozzle is designed for flow rates between 100-380 GPM. To ensure automatic shutoff at lower flow rates (20-100 GPM), Snyder recommends the 17LF fuel nozzle.

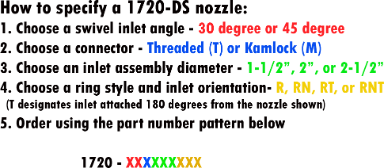

Example: Nozzle shown is 1720-30M2.5RN (standard nozzle, 2-1/2" inlet at 30 degree angle, Kamlock, wheel ring style)

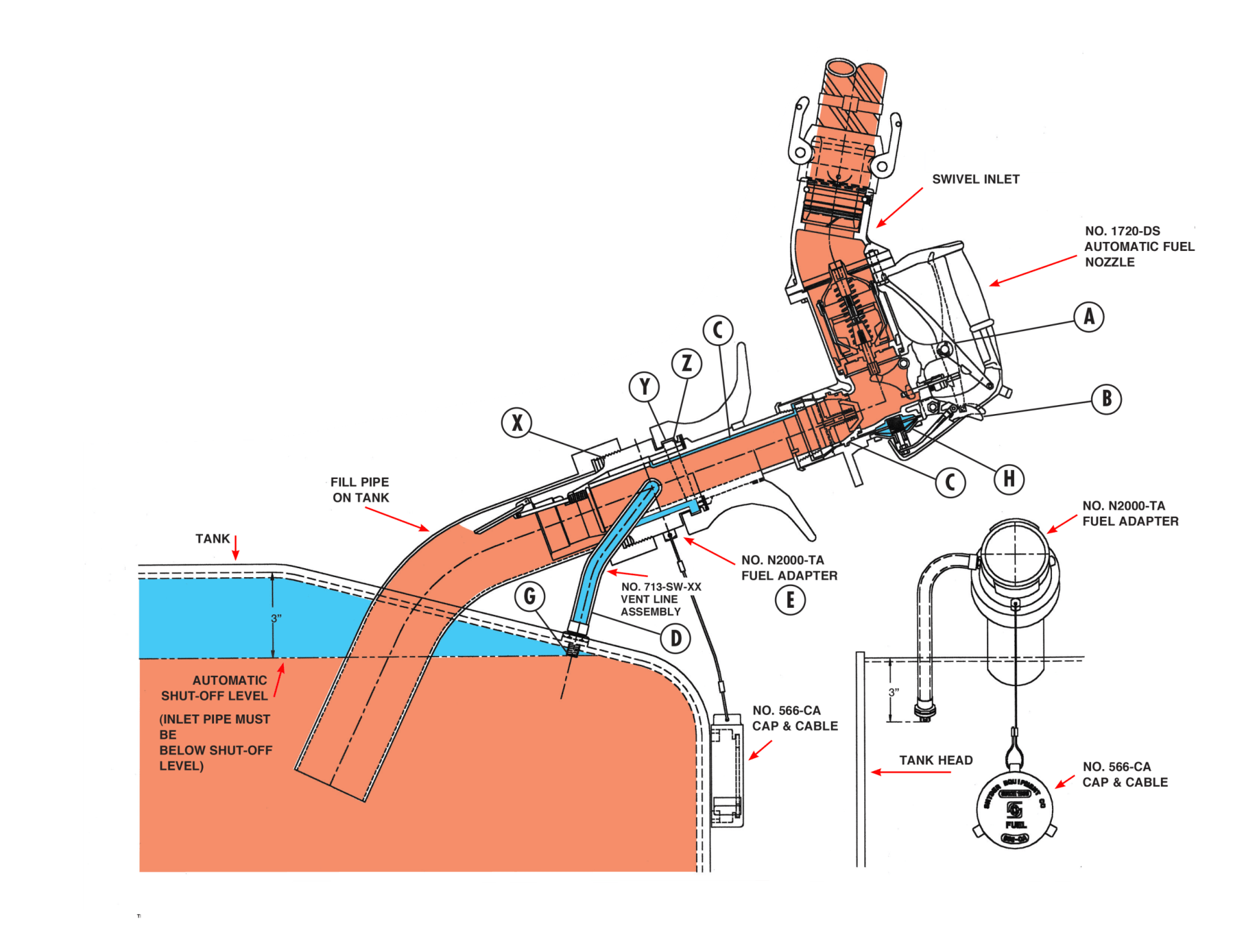

The Snyder II Automatic Fueling System works on a vacuum principle. The system consists of a Snyder 1720-DS Automatic Nozzle and N2000-TA Fuel Tank Adapter Vent Assembly (D and E).

When the automatic nozzle lever (A) is opened, diesel fuel flows through the nozzle and across an internal venturi (C) where a vacuum is created. Diesel fuel flowing into the fuel tank fill adapter (E) draws air from the locomotive fuel tank through the vent line (D) and into the tank adapter (E). Air is then circulated through the internal vacuum tube of the nozzle spout reaching the venturi (C) to satisfy the vacuum, thereby keeping the nozzle open.

As the level of diesel fuel rises in the fuel tank, it will cover the tip (G) of the fuel tank vent line stopping the entry of air into the tank adapter (E). With the absence of air to satisfy the vacuum at the venturi (C), the vacuum activates the automatic shut-off mechanism (H) which releases the operating lever (A) and closes the nozzle.

1720 LF Information

Snyder 1720-LF fuel nozzles – Designed for low flow rate applications

Snyder 1720-LF nozzles are modified versions of the 1720-DS nozzle, designed for flow rates between 20-100 GPM while maintaining automatic shutoff.

Typical uses are DTL (Direct Truck to Locomotive) applications or fixed locations with low flow rates.

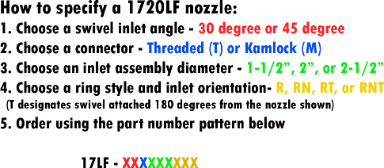

Example Shown: Nozzle is 1720LF-30M2.5RN (standard nozzle, 2-1/2" inlet at 30 degree angle, Kamlock, wheel ring style)

Re-Qualified Nozzles

The following parts and or services will be performed on ALL 1720-DS and 1720LF nozzles when participating in the re-qualification program:

- Inner Assembly (Upgraded to aluminum)

- Gaskets (new)

- Packing (new)

- Fulcrum Lever (new or re-qualified)

- Bleeder Poppet (new or re-qualified)

- O Rings (new)

- Diaphragm Assembly (new)

- Latch Assembly (new or re-qualified)

- Lever Assembly (new or re-qualified)

- Swivel Inlets (new or re-qualified)

- Handle (new or re-qualified)

- Ring (new or re-qualified)

- Seat Ring (new)

- Springs (new)

- Spout Adaptor (new or re-qualified)

- Tail (new or re-qualified) (critical when using with new 2000-TA adaptors)

- Nozzle Strainer (new or re-qualified)

- Body (new or re-qualified)

All items in bold, considered major components. Any nozzle that requires replacement of four (4) or more major components will be deemed beyond repair.

All nozzles will be pre-cleaned, visually inspected, and pre-tested. A complete tear down will then be performed, and all hard parts will be glass bead cleaned, and qualified. The nozzles will be re-assembled, tested, flushed, and packaged for shipment.

Re-qualified nozzles will carry a one (1) year limited warranty from date of shipment.