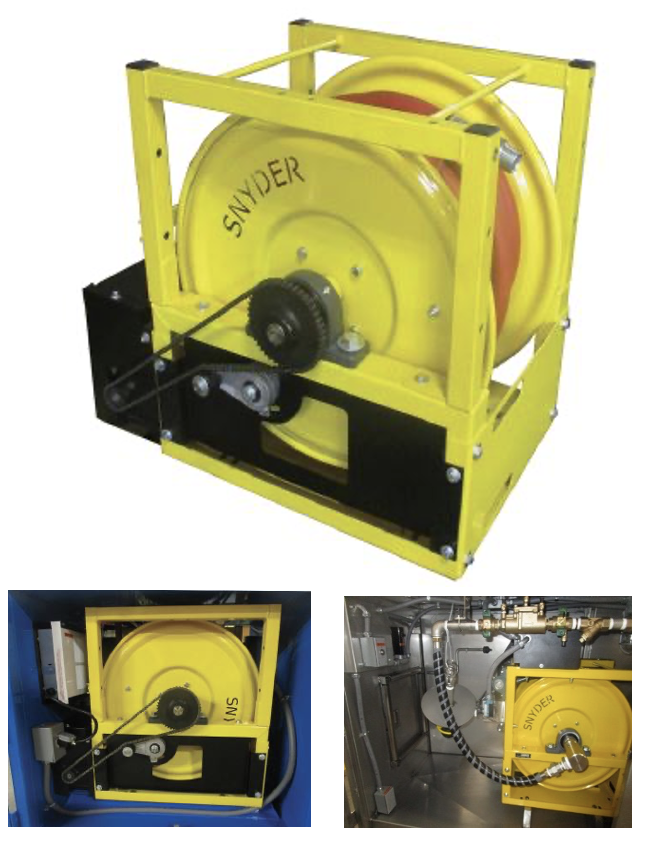

Hose Reels

For New Cabinets, Replacements, or Stand-Alone Applications

Snyder’s hose reels are the heart of our cabinet systems. They are also available as replacement reels or stand-alone units.

Standard hose reels include electric rewind motors and 75’ of working hose length with adjustable rubber hose stops. Options include:

- Left-hand or right-hand inlet swivel

- Alternate hose length

- Special hose and lead-free swivels for potable water applications

- Level-wind assemblies to keep hose from gathering on one side and binding

- Alternate rewind motor placement for cramped spaces

Alternate Reel Systems

Snyder can incorporate spring rewind reels where automatic rewind is not required. Other options include bi-line reels to deliver two fluids in the same cabinet, specialty delivery nozzles, and conversion kits (see REEL-MAN-1005) to add level wind mechanisms to standard Snyder reels.

Integrated Systems

Got a unique reel application? We can create hybrid systems such as mulitple-reel rack systems for air, water, oil, and electrical service, or incorporate other reels into our standard equipment offerings. Avoid the tangles of hoses and cords that can potentially lead to accidents.

Contact Snyder to discuss specialized hose reel systems to keep your service track safe and organized.

FAQS

Got questions? We’ve got answers.

- What regular maintenance is required?

Snyder recommends greasing the bearing blocks in the reel motor clutch assembly every 6 months and greasing the reel bearing blocks and reel swivels annually. White lithium grease is recommended for non-potable applications, available from Snyder under the part number GREASE LITHIUM. Potable swivels require Haynes Lubri-Film Plus grease to maintain potable status. Older reel swivels require a different grease, available under Snyder part number GREASE 880-0089. These are general instructions, follow the instructions in the manual that came with your unit for specific requirements.

- The hose is sticking or hard to pull out. How do I prevent this?

Check for any obstructions or areas inside the cabinet that may be restricting the hose.

The hose may be binding by rewinding primarily on one side. Guide the hose from side to side to rewind smoothly, or consider an automatic level wind system.

The hose can also bind if the rewind switch is held down after the hose has retracted into the cabinet. Generally, the rewind button should be released just as the nozzle is returning into the platform or boom cabinet, and then the nozzle should be placed in the cabinet nozzle storage area by hand.

Older hose reels (generally before 2018) contain a clutch that requires one hard tug to release the clutch. Older reels may also have a reel brake assembly installed next to the tensioner – if so, verify that the reel brake tensioner has not been overtightened.

- The hose won't rewind. How do I fix this?

Check for physical obstructions, and verify that the rewind switch has power and is attempting to rewind. Next, check the chain on the reel and verify that it is still engaged and that there is no slack. Adjust the reel tensioner if necessary. Verify that the clutch in the reel motor is properly engaging.

- How do I change out a reel motor?

General instructions are here (document coming soon). Follow the instructions in the manual supplied with your cabinet for specific instructions.

Excelling Worldwide Since 1936

We are available via fax, email or telephone

Call

417-725-4067

All Rights Reserved | Snyder Equipment, A Division of New York Air Brake LLC

4654 W Junction St, Springfield, MO 65802 | Ph. (417) 725-4067 Fax (417) 725-4846