Filter Vessels

Snyder Fuel Filter Vessels – Providing Clean Fuel for Your Fueling Operations

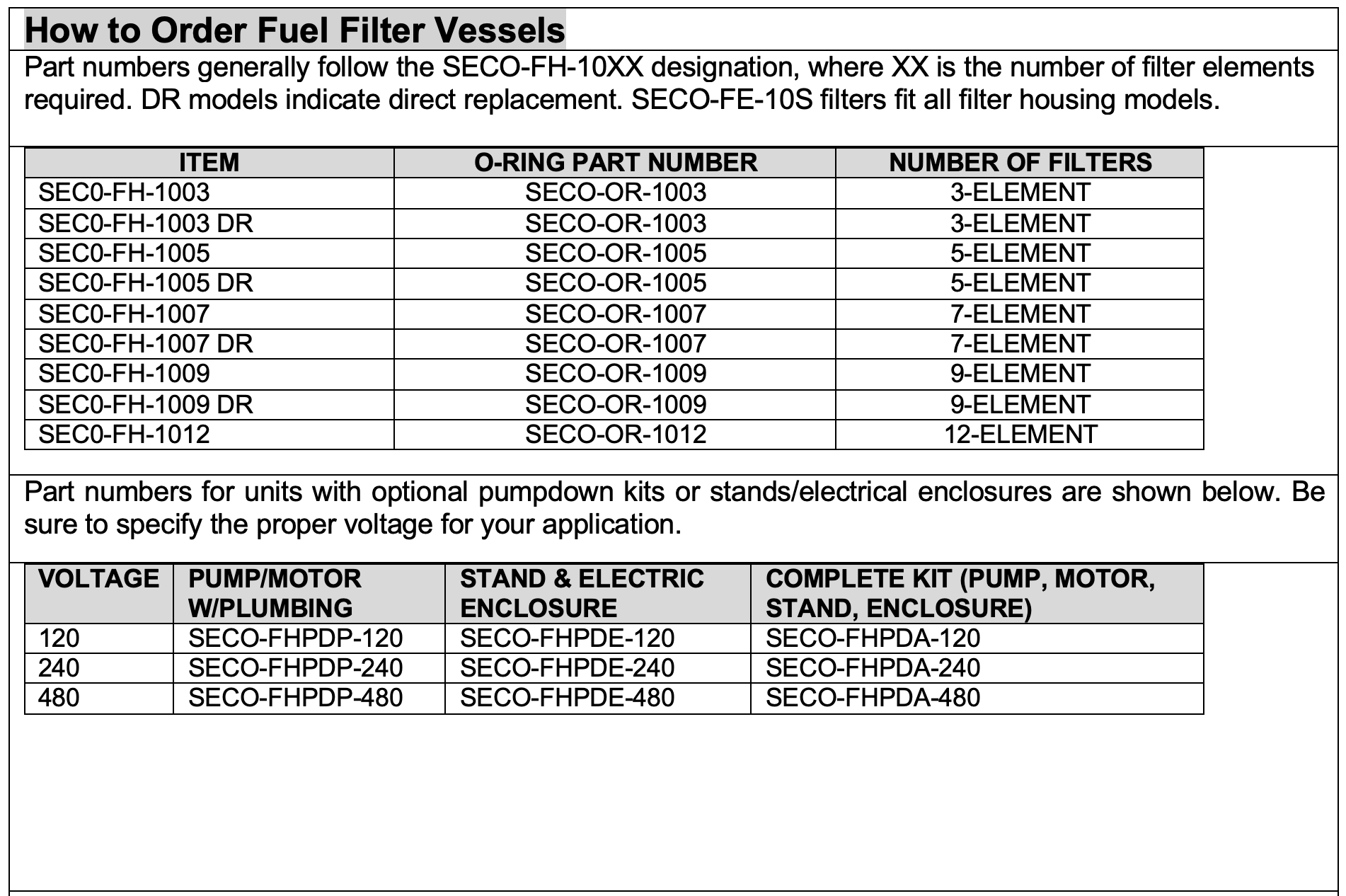

Ordering Filter Vessels

Contact Snyder for other custom options if you have special requirements for your application.

Popular Questions

Got a question? We’re here to help.

- How do I specify a pressure vessel for my application?

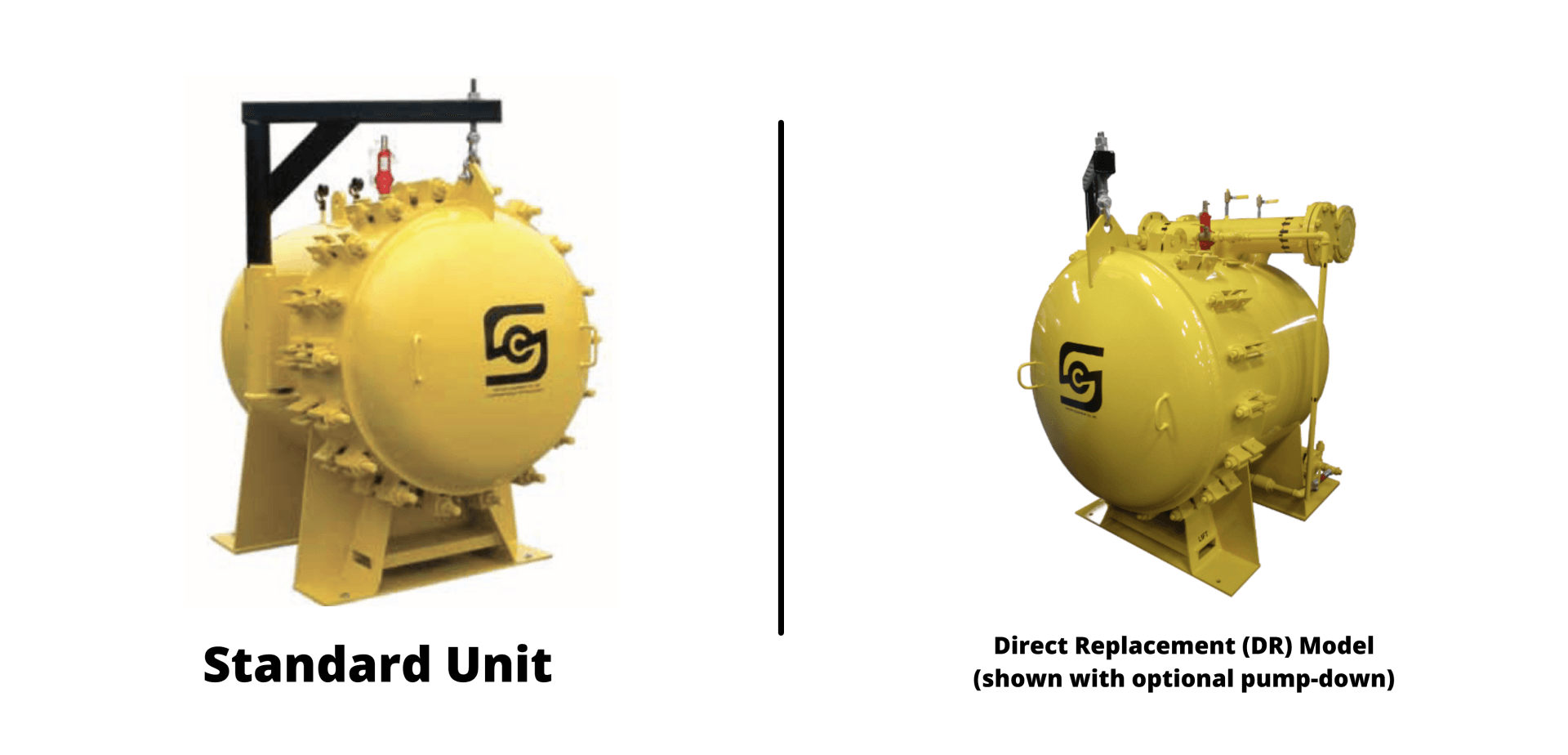

Each fuel filter cartridge is rated for 50-100 GPM. Choose the number of filter elements required (3, 5, 7,9, or 12) to meet your flowrate requirements, the model (standard or direct replacement), and the desired options (pump-down kit, stand and electrical enclosure, or both). If options are chosen, specify the desired voltage rating. Refer to the available filter housings section or to the available filter housings list (link to PRES-INFO-1000) for the proper Snyder part number. Contact Snyder if you need help specifying a filter vessel for your application.

- When should I change filters?

Snyder recommends changing the filters when the differential pressure between inlet and outlet is 25 psi or greater, or the desired flowrate is not acheived during fueling. Your unit may require more frequent changes depending on local conditions.

- How do I change filters in a pressure vessel?

Generic maintenance instructions are located here (link to PRES-INFO-1000). Refer to the manual that came with your unit for specific instructions.

- Which filter does my unit need?

All Snyder filter vessels are equipped with the same filter. Order Part number SECO-FE-10S.

- How many filters does my unit need?

The number of filters required for your unit corresponds to the part number. For example, a SECO-FH-1007 vessel will require (7) SECO-FE-10S filters. There is no difference in filters between direct replacement and standard models.

- How do I specify o-rings?

The o-ring part number for your unit corresponds to the part number. For example, a SECO-FH-1007 vessel will require a SECO-OR-1007 o-ring. There is no difference in o-rings between direct replacement and standard models.

- What’s the smallest particle size that Snyder filter vessels remove?

All Snyder pressure vessels contain filters rated for 10 microns.

Excelling Worldwide Since 1936

We are available via fax, email or telephone

Call

417-725-4067

All Rights Reserved | Snyder Equipment, A Division of New York Air Brake LLC

4654 W Junction St, Springfield, MO 65802 | Ph. (417) 725-4067 Fax (417) 725-4846